Expertise

Digital Transformation

Industrial digital transformation for a smart, sustainable world

As a leading European provider of industrial automation solutions, we use our profound industry knowledge to integrate IT and OT. We provide industrial operating and management systems and enrich this with IT, IoT, and Data to help our clients to be successful in their digital transformation. Our software fully integrates in the client's business so they can serve their end customers even better. “We make the world a smarter and more sustainable place day by day.”

Data

Additude provides consultancy, projects, managed services, and the solutions that our own people developed. In this dynamic world, we are the right partner for digital manufacturing and data intelligence. With our domain knowledge and technological know-how, we provide innovative, future-proof solutions.

Produce smarter, cheaper, and faster

The digital innovations of Industry 4.0 offer plenty of opportunity, but at the same time for a threat to those who do not follow the trends and fail to innovate in time. The question is how and when to begin, because every step may affect the existing processes and business operation. How do you take advantage of the promising but also demanding technological innovations? With whom do you embark on this challenge of industrial, digital transformation?

What makes us stand out is that, as a digital transformer, we do not only have expertise about industrial automation, data, and digitalisation, but also about the domains in which our clients operate. We understand assets and machines, we know the production lines and data flows, and we oversee the entire chain in which clients, partners, and suppliers operate. We know what digital manufacturing can yield for our clients.

With us, the promises of the digital transformation are in good hands. The result: you are assured of a shorter time to market, lower costs, less waste, lower energy consumption, and, consequently, more sustainable manufacturing processes and products. You produce smarter, cheaper, and faster.

Industry 4.0 makes factories autonomous

Until recently, industrial automation was all about digitalisation and connectivity of machines and factories. IT and OT were separated. The human role as "operator" was still key. In the new world, we see autonomous factories where devices, processes, and data come together. IT and OT environments are seamlessly connected. Data enable operational excellence at a much higher level, integrating machine operation with the relevant ERP systems. The CFO can see and influence (manufacturing) processes. Smart and cheap manufacturing becomes a shared responsibility for IT and OT.

Industry 4.0 drivers for Smart Cities and Industry

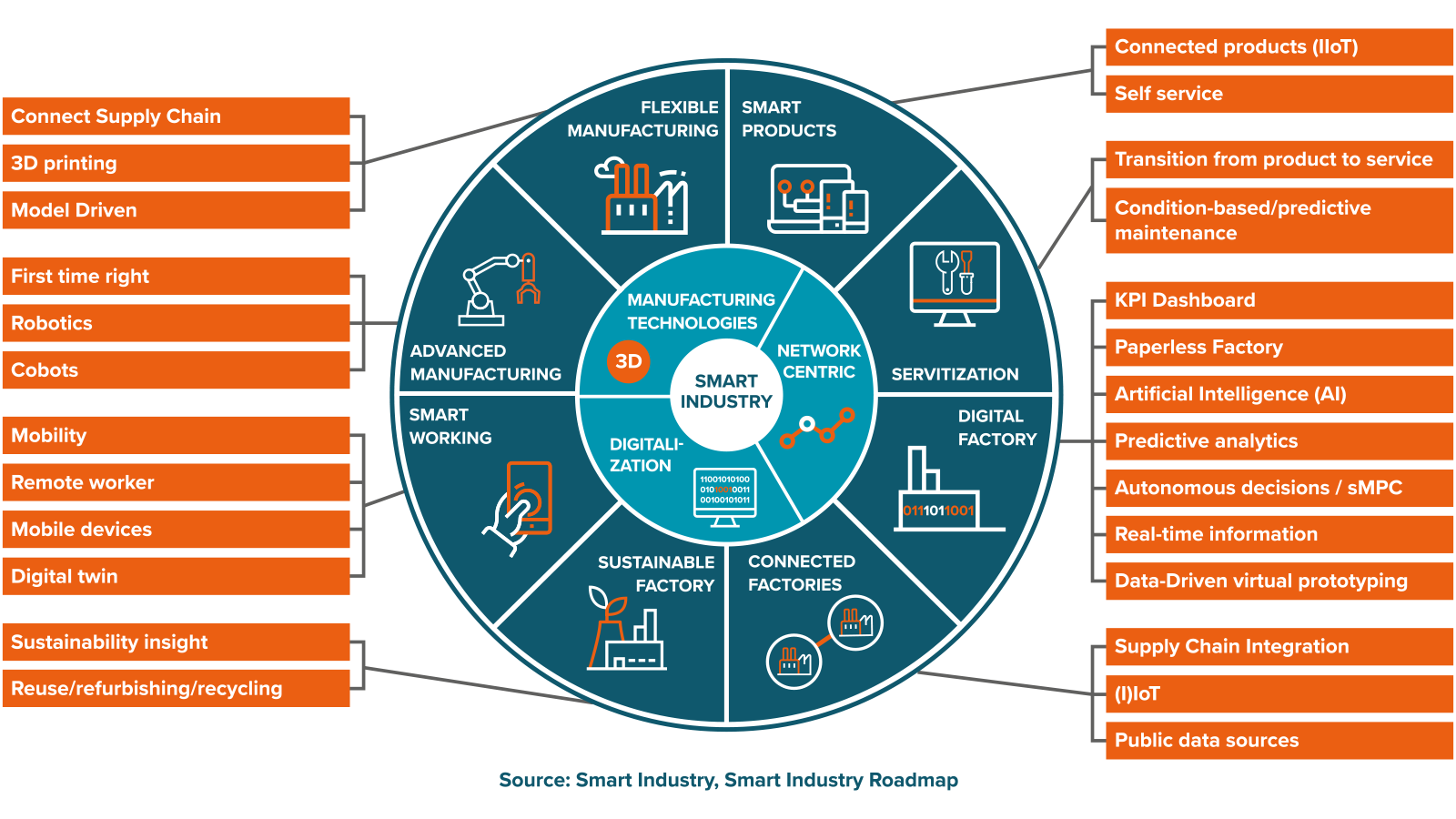

The impact of Industry 4.0 and the digital transformation is summarised in the figure above. Data intelligence is involved everywhere, connectivity and advanced technology are crucial for the entire chain. Our role is to guide our clients through this transition. We help to design self-operating factories and connect them to the supply chain. With the underlying data architecture, we connect ERP systems with WMS and MES systems. We link the client's needs to the factory's capacity. We expand real-time data and customer data with model-based control. We use IoT sensors to visualise minor defects and prevent imminent down-time. We combine data intelligence and software to develop self-learning models implemented in the business operation. This enables you to predict and prevent malfunctions and maintenance. You make the controlled switch to remote asset management, remote maintenance, and remote diagnostics. All IT solutions that will boost the development of new business models and production methods.

A bit smarter day by day

We are seeing changes, in all fields, that impact your current working and manufacturing methods. Smart asset management, control, and insight are core values for us. By monitoring machines, processes, and people in real time, you enable yourself to act pro actively. You make data-driven decisions based on accurate and consistent evaluations. You gain knowledge by modelling evaluation procedures and criteria. The stability of your manufacturing processes increases, while the energy consumption and production time are reduced. You make products with a higher quality, at lower costs and with less waste. We are your trusted partner who will let you look to the future with confidence and benefit from the advantages of digital transformation and digital manufacturing. We bring people, technology, and ideas together by linking our knowledge of your market to innovative, integrated solutions for your company, product, or project. Our challenge is to help you make the world a smarter place day by day.

Digital Twin

Digital Twin runs a digital copy of a complete factory or a single machine parallel to the reality. This makes it possible to visualise their functioning and processes, and to measure and predict their behaviour. We log data for each part and each step of the process. We can also virtually replace or add parts to monitor and analyse the impact.

What we offer

We provide proven solutions, high-quality (certified) services, and dedicated people who know the entire digital transformation chain inside out. That makes Additude the ideal partner for future-proof and long-term cooperation.

Our approach

- We start from the client's need, the problem, not the technology

- We think from end to end, from idea to management

- We combine 40 years of domain experience with technical expertise

- We benefit from the potential of 1600 highly trained professionals

- We take responsibility for the final result