Expertise

Connected Supply Chain

Combined with the explosive growth of cloud computing, big data and IoT, this asks for modern, flexible logistics software. Software that quickly shares information, is easy to expand, and guarantees flawless communication with other systems.

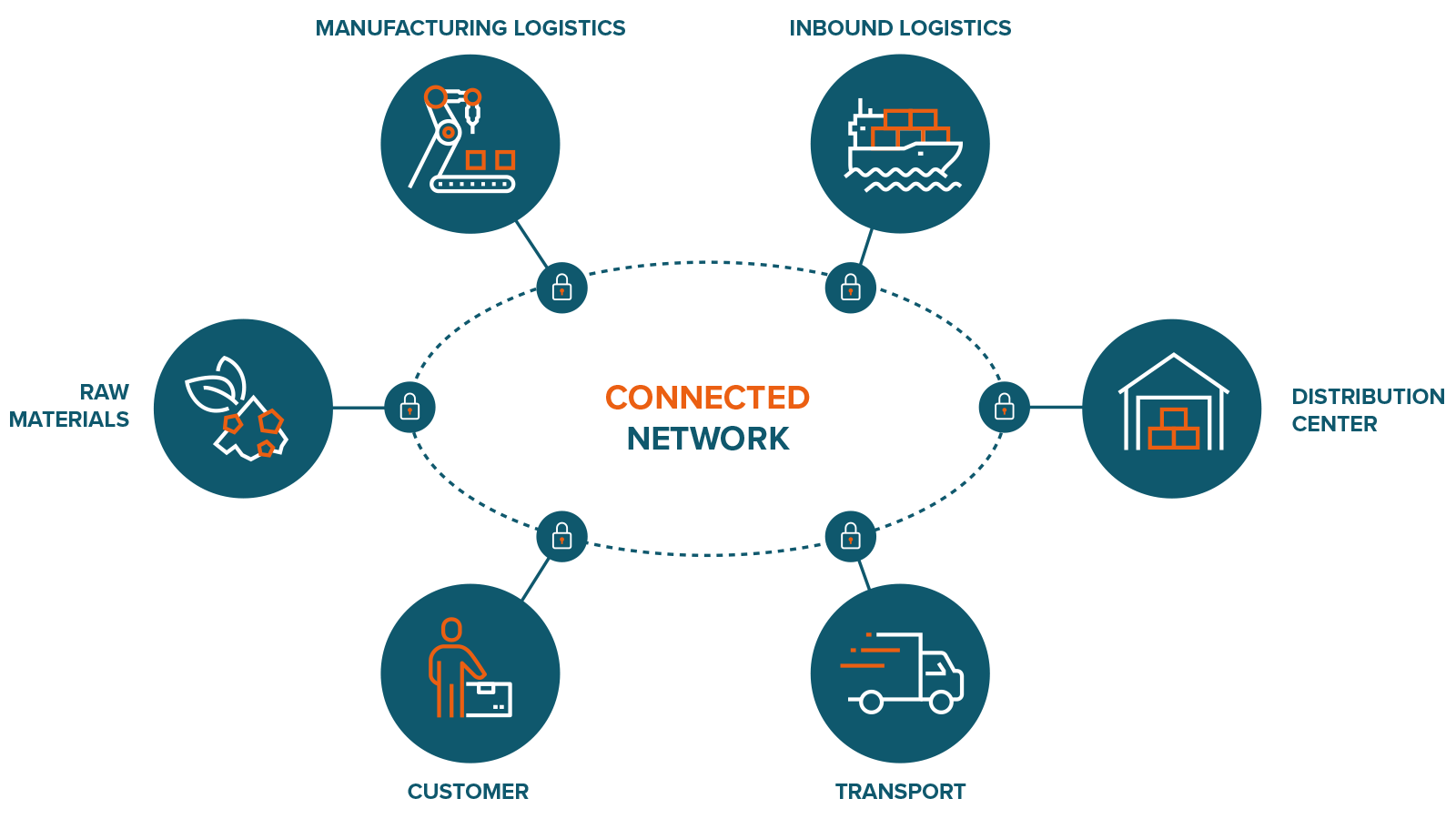

The world of logistics is teeming with terms for supply chain improvement; end-to-end visibility, supply chain sustainability, chain integration, collaboration. Whatever you prefer to call it, supply chains will only be improved truly if all links are 100% visible, can be managed in real time, and connect seamlessly to each other.

All steps under control, from inbound to outbound

Whether you are a Supply Chain manager, logistic manager, or procurement manager in the manufacturing, trade, or retail sector, it all starts with overview and insight in the supply chain. It is about complete control of all steps from inbound to outbound.

Improving your supply chain starts with overview and insight

In day-to-day practice, we often see that manufacturers, trading companies, and retailers do not have a clear overview of the entire supply chain. Orders are placed, lead times agreed, but then what? Too many orders are lost in some sort of black hole and there is too little intel on what goes on in the logistic chain. Feedback and status updates are often given by phone, email, and Excel. That makes management nearly impossible and, by definition, reactive. The result: long lead times, large stock, too high logistic costs, and clients not getting what they want due to a discrepancy between demand and supply.

The connected supply chain is a next step in digitalisation, and offers the following benefits:

- Supply chain visibility

- Reduction of costs and stock

- Higher efficiency, less handiwork

- All information visible in one place.

- Looking ahead instead of picking up the pieces

- Sustainability (CO2 reduction thanks to lower number of transports).

Additude combines logistic domain knowledge with a profound expertise of automation and digitalisation, and offers a complete package of solutions and products to automate the supply chain from inbound to outbound and to make it more visible:

Logistics for the distribution chain

It is of vital importance for warehouses to supply their clients quickly and without any problems. Mistakes and delays in order picking and shipping will inevitably lead to unhappy clients. We realise and manage all systems that guide the (warehouse) process, such as an Engineered Warehouse Management System (WMS) or a Configured WMS. Our WMS is based on and tailored to the specific situation. We also control the equipment with a Warehouse Control System (WCS), such as conveyor belts, automatic warehouses, voice picking, Pick/Put-To-Light guidance, and robots. To achieve this, we integrate our custom-developed solutions with existing systems including ERP and WMS.

Logistics for the production chain

It is of vital importance for production companies to bring in and use raw materials for the production process "just in time". To create a smooth workflow, we take care of the control of equipment and robots, automate the process, and integrate the various systems with an ERP or WMS. We realise cost and time saving solutions to meet our clients' demands and help them to improve the quality of their end products. With optimum execution and visibility, we make sure that the right amount of goods arrives at the right place and with the right quality, exactly when you need them. Our expertise enables us to direct your production activities and optimise the flow of goods from your suppliers.